Starting a Nylon production business

in Nigeria is very profitable. This is actually a business anybody can venture

into and start making some real profits. Nylon production business is quite profitable.

The demand for Nylon in Nigeria is really on the high side due to the many uses

of nylon such as shopping, packaging, bagging, etc.

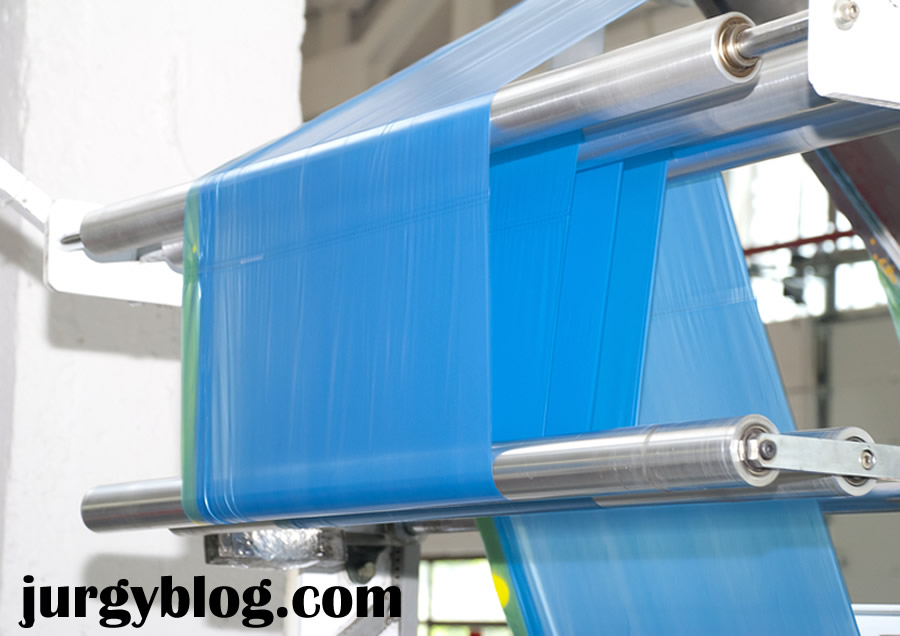

Furthermore, Nylon production process

actually begins with the raw material (B.A.S.F or Escorene or Dow) being poured

first into the heating and melting unit of the extruder machine. After that it

is then blown under pressure through a medium after it has first been

transformed into the liquid state. Then it is cooled, producing polythene

sheets which later become converted to bales ready for cutting and sealing.

Types of Polythene Bags in Nigerian Market

1.

High density polythene nylon bags:

This particular one is the commonly used ones due to their many qualities such

as strength, versatility, and durability. The high density polythene nylon bags

are commonly used as garbage bags, for packaging, also in pharmaceuticals, as

disposables, etc.

2.

The low density polythene nylon bags:

This particular one is mainly used for water sealing, clothes packaging, bread packaging,

food wrapping, etc.

Furthermore, before you venture into

nylon production business in Nigeria there are things you must first consider.

1.

Acquire the experience: Before you

venture into the Nylon production business you need to take out time to learn

everything you can about the business. You need to take out some time to work

in a good and reputable nylon production industry for some period in other to

gain some useful experience and develop yourself. Another ways you can develop

yourself is by attending seminars and trade workshops. You can still source for

advice from people who are in the nylon production business.

2.

Look for capital: The capital needed

for the business will depend on the size or scale and scope of the operation.

If you don’t have a lot of money you may want to consider obtaining loans to

generate the start-up capital. Capital is needed to cover expenses such as land

purchase or lease, labour, equipment’s, electricity and generator, and other

additional expenses. For the equipment you will need about #16,000,000 for the

machines if you want to get them imported, or #8,000,000 if you want to get the

locally made one. To actually venture into nylon production business in Nigeria

you will need to have a budget of #10,000,000 to #30,000,000.

3.

Get a very good Land: You really need

to secure a very good land that will accommodate your nylon production plant. You

can locate your nylon production plant close to your source of raw materials

and market in other to cut back on transportation expenses. On the other hand,

you will really need a space that is big enough to contain all the machines for

the nylon production.

4.

You need hire workers: You will need

to hire some workers for the whole nylon production process. First and foremost

you need to get the services of good engineers to help with the installation of

the machines. You will also need sales executives, machine operators, product

managers, truck drivers, etc. Just make sure you recruit very experienced hands

into your nylon production business.

5.

You need to carryout a market survey:

Before you venture into the nylon production business it is very important you

carry out a proper market survey to actually determine who your target market

is.

The following groups can make up the

target market for your nylon production business; Traders, Schools, Pharmacies,

Water production companies, Eateries and restaurants, Supermarkets, Hospitals, Bakeries,

Laundry, Fashion stores, etc.

Some things you will need

The raw materials: The raw materials

needed for the nylon production business are all by-products of petroleum such

as Dow, Escorene. Others include Master Berg and A.S.F.

Post a Comment